I’m about to embark on establishing a new fishroom, so thought I’d start a thread chronicling the progress. I never do anything conventionally, so as this evolves some of the many quirks in this build will be revealed.

As a start, I thought I’d document how I went about acquiring the bulk of the tanks for the room.

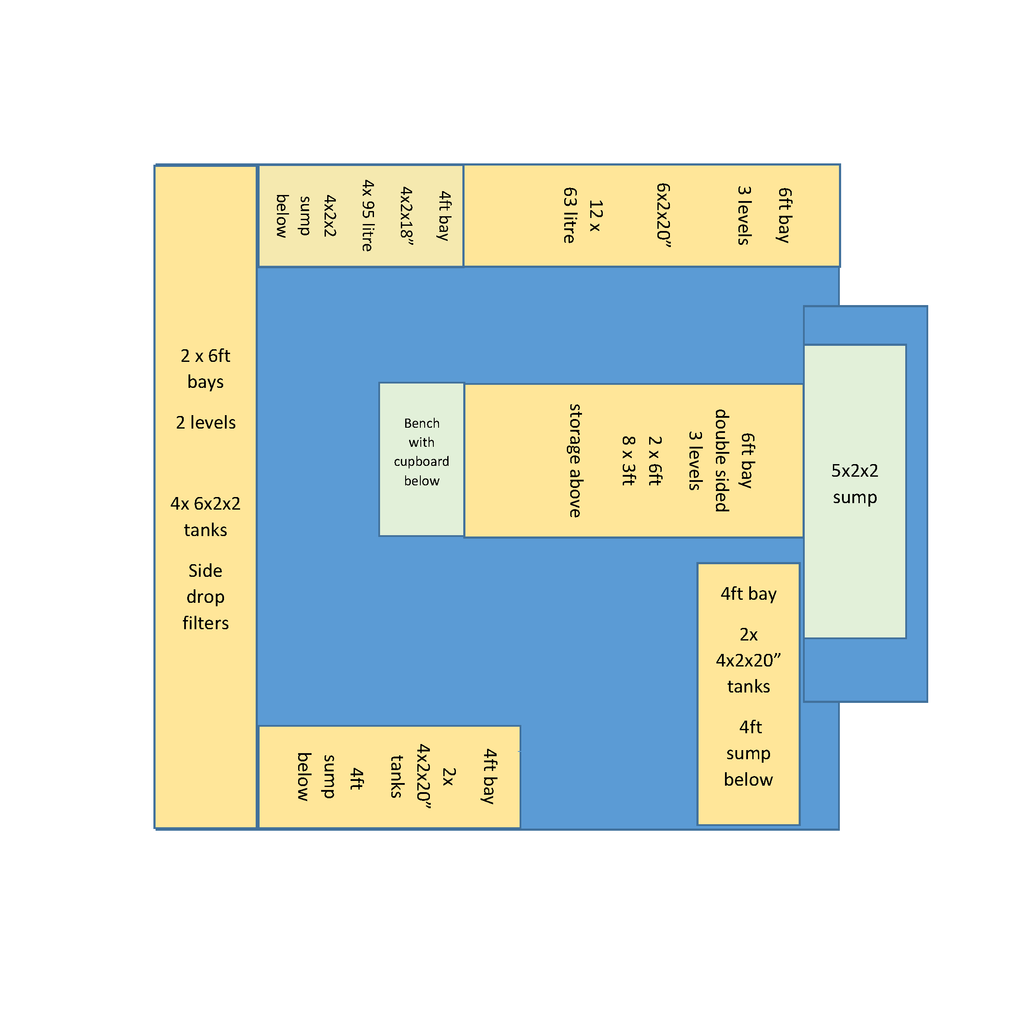

I currently have two small, rather modest fishrooms. The first one I set up in our cellar, and the second in the partitioned off corner of our shed. This third room is again pretty modest, but will roughly double the tank volume I’m currently running.

I like pallet racking for my tanks, so was keen to use it again this time round. If you’ve ever used pallet racking in an area with limited ceiling height you would understand the limitations it imposes on tank sizes. Essentially, you get a better result if you have tanks custom built to suit the constraints imposed by the available shelf heights.

It would have been easy to have tanks built locally, but we have two choices for custom-built tanks here in Adelaide – cheap but poorly built, or well-built but harder on the pocket. That makes it difficult when you want to fit out a whole fishroom and don’t have an unlimited budget.

I saw the contents of a small fishroom advertised for sale and realised it would be ideal to form the basis for my new room. Three bays of pallet racking with tanks of various sizes, all good for what I want to do, plus all of the other gear that goes with keeping fish. The more I looked at it, the better it appeared. Only problem was that it was in Sydney – half a continent away. Never let a tiny problem like that get in the way of a determined woman!!!! A spent many hours working out how it could be accomplished.

The economics of hiring a truck and driving over to pick the gear up just didn’t work for that number of tanks. Talking it over with a number of people it became obvious that the answer was to have additional tanks built in Sydney to add to the secondhand ones. So an order went in for four 6x2x2’s and one 6x2x20”, all with side-drop filters, plus another 6x2x20” I still needed for the existing fishroom.

I picked up the truck on Thursday morning and headed home to collect my gear and the packing materials I’d accumulated.

. . . . and Captain, my travelling companion for the trip.

Left home at lunch time and drove through the night, stopping every couple of hours for a short break, or to have an hour or two sleep in the cab of the truck in one of the many truck stops along the road. Arrived at the Camden caravan park in the western suburbs of Sydney mid-afternoon on Friday feeling very tired!

Sydney had put on the weather for my arrival – it was blowing a gale and there was a weather warning in place. L By evening the wind had dropped, so I pitched the tent, but still decided to sleep in the back of the truck overnight.

Saturday morning it was off to Abyss Aquariums to pick up the custom tanks they had built. This company is very impressive with what they have achieved in a relatively short space of time. They are a retail aquarium shop, but also manufacture tanks on site.

I admit I was relieved to see the tanks completed. Even as I was driving over I received a message from Ben which included a photo of the glass in a stack on the bench still waiting to be siliconed together. Nothing like cutting things fine!!!

Being at Abyss has the feel of a kid-in-a-lollyshop about it. I was pretty excited to see my nice brand spanking new tanks sitting on the benches, but they were absolutely dwarfed by some of the other tanks currently under construction. Ben showed me the glass sitting there waiting to be turned into the big shark tank which will form the front façade of the shop. The glass is 30mm thick. Makes my 10mm thick glass look positively flimsy!!!!

The guys were advising me to pack the truck without padding between the tanks. The theory is that if they can move due to “give” in the material around them, then they will move during transit, and that can cause breakage. Packing blankets were laid on the floor of the truck, and the tanks were loaded standing on their ends with nothing other than thin boards between them to stop any direct glass-to-glass contact. They were packed in tightly with no gaps between them, and the six tanks were secured using a single webbing strap under only a moderate amount of tension. I’m rather sceptical, but I take the advice of the guys with the experience . . . . . .

Edited by humbug, 28 May 2015 - 11:46 PM.